We're stoked to unveil the official launch of our new cutting-edge foil production line. And what better way to debut it than with the introduction of our new flagship GP windsurf race foil? (Stay tuned for the official launch of the new foils in the next couple of weeks.)

To borrow a line from one of my favorite Guy Ritchie movies, "The Gentlemen," "enough with the foreplay, now show me how the sausage is made."

We utilize a blend of resin and carbon materials; some foils are based on wet layup, while others rely on prepreg carbon. Depending on the handling requirements, we employ different methods to store, process, and prepare the materials.

The process kicks off in the cutting section, where we cut the raw materials according to the layup schedule and stack them in readiness for mold filling. Precision is key, as any over or under filling of the mold would lead to performance implications and deviate from the original design of the part.

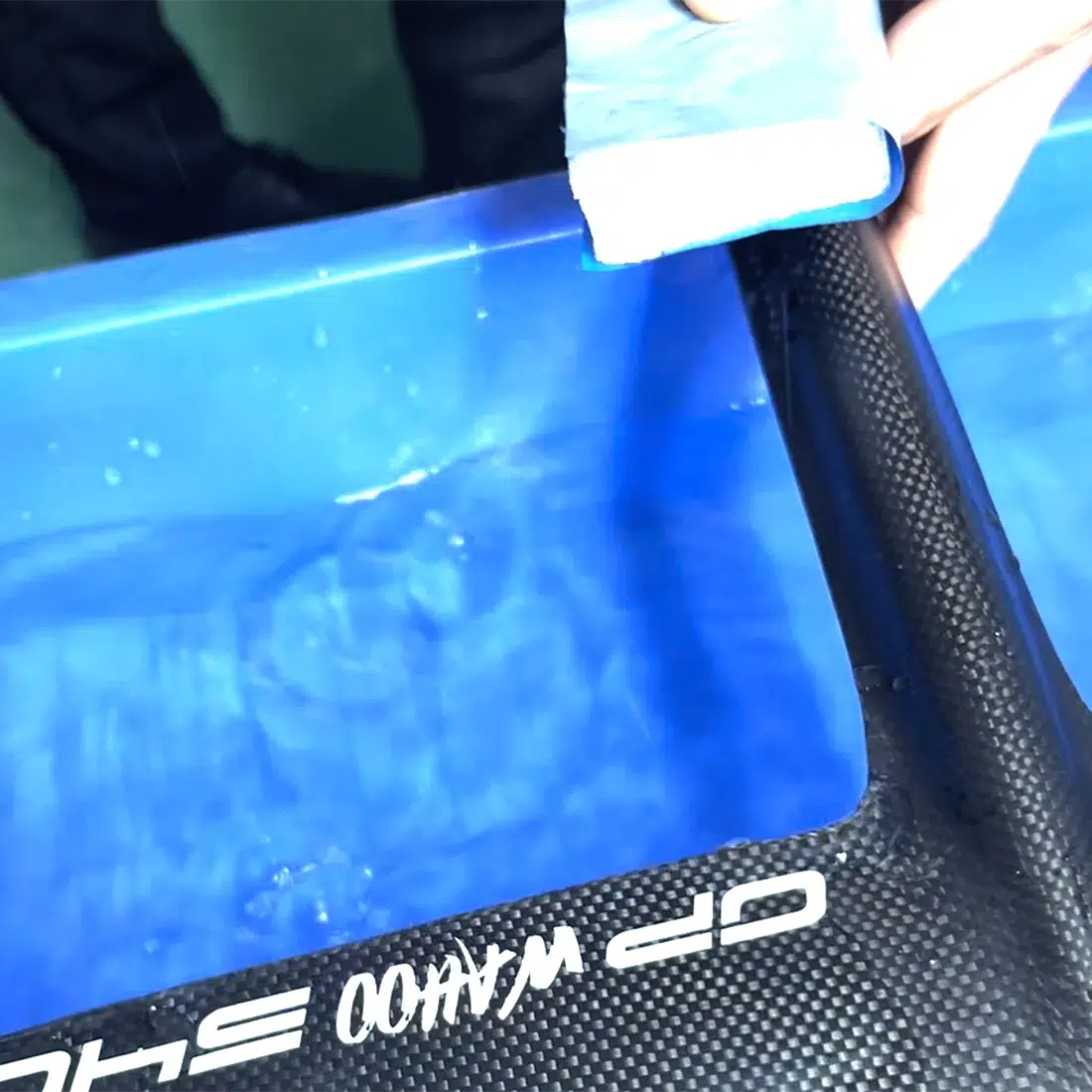

Once the various materials are cut and stacked, they're laid out in the molds. These molds, constructed of sturdy steel, endure significant force from hydraulic presses and heat during the foil manufacturing process.

Every component of our new GP windsurfing foils undergoes a very detailed measurement and testing process in our lab in order to make sure they conform to a strict specification and guarantee the ultimate performance.

It took years of development and refinement to perfect the design and manufacturing process of our foils. While it may not be as glamorous as the social media posts showcasing us using them, there's a geeky coolness to the process that's hard to beat. Our new production line has truly elevated the art of foil building to a whole new level.

Now that you know how they're made, the next time you're at the beach gearing up for some fun on the water, you'll have a better appreciation for what goes into getting you there.

Enjoy the ride, and we'll see you on the water!

The F4 Foils Team